Understanding Drop Testing

Drop testing is a critical procedure used to evaluate the impact resistance and durability of a product. This test simulates the conditions a product might face during handling, transportation, and usage. By subjecting products to controlled drops, manufacturers can identify potential weaknesses and ensure their products can withstand real-world conditions.

How Drop Testers Work

A Drop Testing is designed to simulate free-fall drops from various heights and angles. The device typically consists of a platform to hold the test sample, a mechanism to release the sample from a predetermined height, and a surface to record the impact. Here’s a step-by-step breakdown of the drop testing process:

- Preparation: The product is placed on the Drop Tester’s platform.

- Selection of Drop Height: The desired drop height is set. This can vary based on the product’s intended use and industry standards.

- Release: The product is released, free-falling onto the impact surface.

- Analysis: After the drop, the product is inspected for any damage or deformation. Data is collected to assess the product’s durability and performance.

Benefits of Drop Testing

- Quality Assurance: Drop Tester Price ensures that products meet quality standards and can withstand handling and transportation stresses.

- Cost Savings: Identifying and addressing potential weaknesses during the testing phase can prevent costly recalls and product failures in the market.

- Compliance: Many industries have specific standards and regulations regarding product durability. Drop testing helps ensure compliance with these standards.

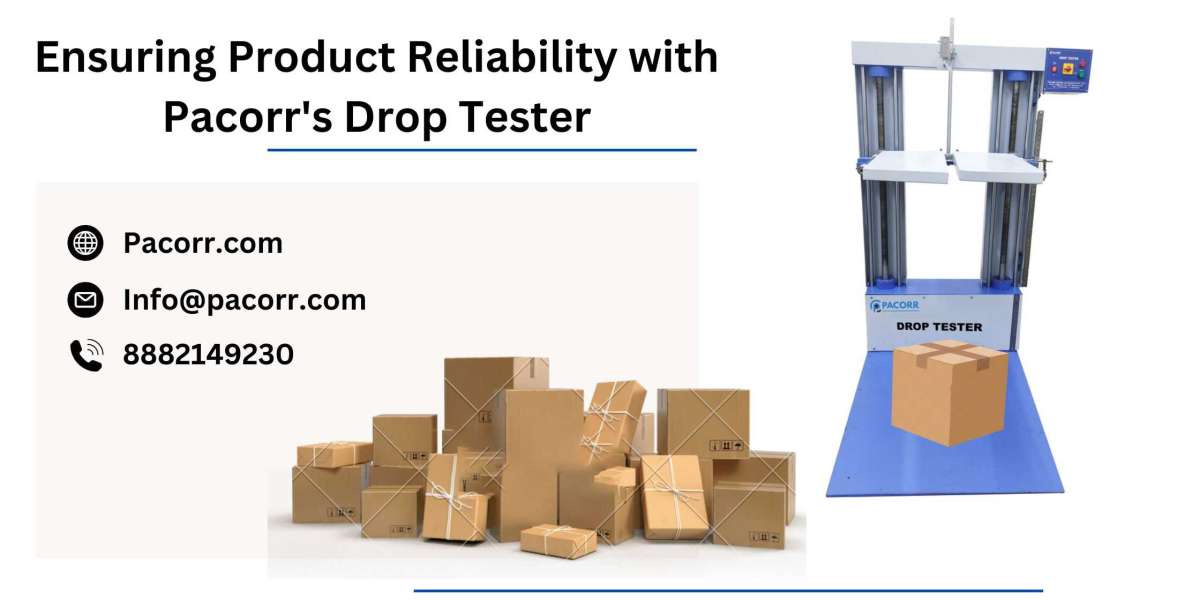

Why Choose Pacorr Drop Testers?

At Pacorr, we understand the critical role that reliable testing equipment plays in quality control. Our Drop Testers are designed with precision and durability in mind, offering several key advantages:

- Advanced Technology: Our Drop Testers utilize cutting-edge technology to provide accurate and repeatable results.

- Versatility: Pacorr Drop Testers can accommodate a wide range of products, from small electronics to large packages.

- User-Friendly: Designed with ease of use in mind, our testers feature intuitive controls and clear displays, making the testing process straightforward.

- Customization: We offer customizable options to meet the specific needs of different industries and testing requirements.

Applications of Drop Testing

Drop Impact Tester are used across various industries to ensure product reliability and safety. Some common applications include:

- Consumer Electronics: Ensuring gadgets can withstand drops and impacts during everyday use.

- Packaging: Testing the durability of packaging materials and designs to protect contents during shipping.

- Automotive: Evaluating the impact resistance of components and materials used in vehicles.

- Medical Devices: Ensuring medical equipment remains functional and safe after drops and impacts.

Conclusion

Investing in a high-quality Drop Tester from Pacorr Testing Instruments Pvt Ltd is a crucial step in ensuring your products meet the highest standards of durability and reliability. Our commitment to innovation, precision, and customer satisfaction makes us the preferred choice for industries worldwide.

Visit Pacorr Testing Instruments Pvt Ltd to learn more about our Drop Testers and how we can help you achieve your quality assurance goals. Contact us today to discuss your specific testing needs and find the perfect solution for your business.