Increasing downcomer prime width is a regular methodology to handle choking problems. It lowers the highest froth velocity, allowing improved vapor disengagement. The key's to use a balanced design to deal with both the liquid and vapor loads throughout the column. Apart from totally different column internals, tray column and packed column have similar layout for external flow association.

thoughts on "Types of Trays in Distillation Columns"

Because of the CMO assumption, both liquid and vapour flow charges stay fixed throughout the tray. As nicely, the vapour leaving the tray with composition $ y_n $ is taken into account to be in equilibrium with liquid leaving the tray with composition $ x_n $. The plate distillation column stands at a top of __ and a diameter of eleven.87 inches. There are 12 plates in the column the place, from the bottom-up, there are four sieve trays, 4 ballast trays, and 4 bubble-cap trays. A pump is used to feed the streams into the column and there are pumps on the condenser and reboiler (to overcome head loss).

This method doesn't improve capacity in a linear fashion. Generally talking, capacity will increase with the square root of the tray spacing.High capacity deck designs normally use smaller orifices. Smaller sieve holes or valves have a tendency to scale back localized momentum of the vapor flowing through the orifices. Essentially, smaller streams have a more difficult time penetrating the froth on the tray deck and subsequently do not carry as much entrainment upward. With conventional cross-flow trays, aerated froth enters the downcomer from the tray above. As the froth flows into the downcomer, a lot of the vapor disengages from the liquid and returns to the tray area above, leaving a degree of clarified liquid within the downcomer that flows to the tray below.

This method doesn't improve capacity in a linear fashion. Generally talking, capacity will increase with the square root of the tray spacing.High capacity deck designs normally use smaller orifices. Smaller sieve holes or valves have a tendency to scale back localized momentum of the vapor flowing through the orifices. Essentially, smaller streams have a more difficult time penetrating the froth on the tray deck and subsequently do not carry as much entrainment upward. With conventional cross-flow trays, aerated froth enters the downcomer from the tray above. As the froth flows into the downcomer, a lot of the vapor disengages from the liquid and returns to the tray area above, leaving a degree of clarified liquid within the downcomer that flows to the tray below.Cross-Current Packed Grid Tray for a Product-Concentrating Column

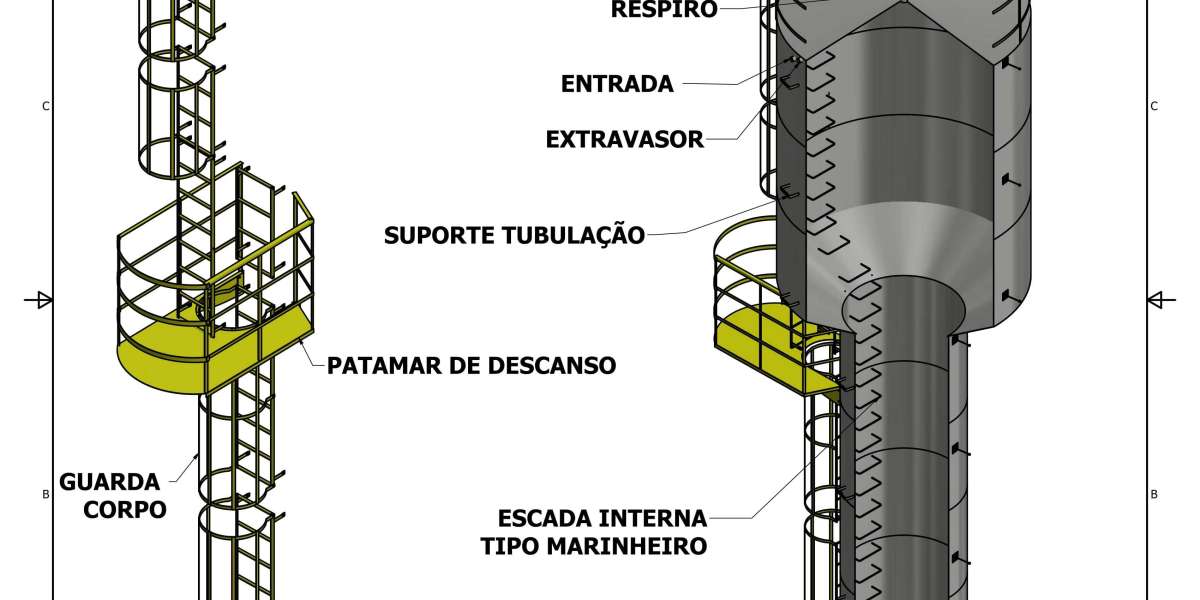

As proven in Figure 2.1 with a tray column, the feedstock combination is usually launched close to the middle of distillation column, to a tray generally identified as feed tray. The feed tray divides the column into the enriching or rectifying section with all of the trays above the feed tray, and the stripping section with all of the trays under the feed tray. Depending on the feed condition, the feed enters the feed tray and splits into a vapour stream and a liquid stream, adding to incoming vapour move and liquid flow on the tray. The vapour generated within the reboiler flows up into the bottom tray, and finally exits the highest of the column. It is then cooled by the condenser to liquid once more, and the overhead liquid is held in a holding vessel generally identified as overhead drum. The overhead liquid is break up into two streams, one recycled back to the top of the column as reflux, and the other removed from the column generally recognized as the distillate or high product.

2. Tray Column Performance and Design

The perform of a tray is to mix the vapor and liquid collectively to form a foam. Vapors bubble up via the tray sieve holes, the place the vapor comes into intimate contact with the liquid. The fluid on the tray is a mixture of vapor and liquid in the form of froth or foam. This foam ought to separate back right into a vapor and a liquid on the tray and within the downcomer. If the froth can not drain rapidly from a downcomer onto the tray under, then the foamy liquid will back up onto the tray above. The sieve tray is the simplest kind of cross-flow plate.

Tell Me MoreAbout Curry Water Trucks & Tanks

If you want a water truck for street dust control or dust suppression in your job web site, we're here to help. We ship all our vehicles globally, so there is no location too far for http://www.annunciogratis.Net/author/wxomariajli us. Where $\sigma$ is floor tension of liquid (N/m) and g is gravitational constant (m/s2).

Sintex FRP Underground Water Storage Tanks, 10000 L

Sintex FRP Underground Water Storage Tanks, 10000 L Not only is it simpler to install, but you’ll get financial savings on labor prices and annual inspections. The average price to put in a 1,000-gallon above-ground water tank is around $1,seven hundred. If we have a look at the technical details of those tanks; We see that its weight is 180 kilograms, its peak is 240 centimeters, and its materials thickness is 10 millimeters. In the sleeve part, a brass sleeve is used to make sure its suitability for meals. Usage temperature rates are between the coldest -5 levels and the most popular +50 degrees. In addition, the lid part can be produced utilizing polyethylene raw material when it comes to its suitability for meals.

HDPE Sintex Water Tanks

We supply tanks in a spread of materials, such as PVC, metallic, and polyethylene. We also stock leading brands, including Norwesco, Snyder, and Ronco. Labor can vary drastically, as somebody who only wants an emergency tank can typically set it up themselves. But, somebody going for an underground water tank will want an excavation crew to dig out the area. With these issues in mind, count on to pay anyplace from $500 to $2,000 in labor prices. A water heater doubles as a water tank and might hold wherever from 50 to eighty gallons of warm water at any given time.