Packed columns are called continuous-contact columns while trayed columns are called staged-contact columns because of the manner in which vapour and liquid are contacted. Both reservoirs and standpipes present ground-level water storage that can be built to nearly any capability and dimension. Distillation columns are utilized in petrochemical, chemical and pharmaceutical industries to purify and separate numerous chemicals, distillation columns are additionally used within the manufacturing of alcoholic beverages. The floor enhancements have been chosen to maximise liquid spreading. These traits have a tendency to level out vital performance advantages in low pressure and low irrigation fee purposes. This specification covers the design, fabrication, and erection of a geodesic clear span aluminum dome roof structure(s) designed and manufactured with appurtenances as required on the contract drawings and specified herein.

Packed columns are called continuous-contact columns while trayed columns are called staged-contact columns because of the manner in which vapour and liquid are contacted. Both reservoirs and standpipes present ground-level water storage that can be built to nearly any capability and dimension. Distillation columns are utilized in petrochemical, chemical and pharmaceutical industries to purify and separate numerous chemicals, distillation columns are additionally used within the manufacturing of alcoholic beverages. The floor enhancements have been chosen to maximise liquid spreading. These traits have a tendency to level out vital performance advantages in low pressure and low irrigation fee purposes. This specification covers the design, fabrication, and erection of a geodesic clear span aluminum dome roof structure(s) designed and manufactured with appurtenances as required on the contract drawings and specified herein.Distillation Column Internals

The major liner is suspended around the inside of the highest of the tank wall structure using stainless or galvanized mounting hardware and strengthened edging. Preliners are non-woven geotextiles positioned across the inside of the tank wall construction and placed on the concrete foundation. Preliners shield the principle water containment liner from harm and permit moisture to wick away from the space between the tank walls and the main liner. The edges of staves used for smaller diameter and TinyTimber tanks are also machined to a correct bevel for the tank wall curve.

How to establish relation between flow rate and height of the water column of the tank?

As properly, the above process is often used to troubleshoot operation problems in sensible distillation operations. For caixa d água Taça a distillation column design, if the overall column effectivity, $ E_o $, is thought, then the actual variety of trays required or column height for a specified separation can be decided. TimberTanks are water storage tanks that mix the ageless beauty of wooden with the durability of galvanized steel roofs and the fashionable expertise of versatile membrane liners for water containment. Wood staves are custom milled to type a barrel form and are banded together with galvanized steel bands to retain the round shape. The galvanized metal roof incorporates factory fashioned and punched high rib roof panels which create a durable and weatherproof roof structure.

Pros and Cons of Distillation Columns

The assumption can be justified by simply checking the warmth of vapourization of all the parts. For a binary system, this means that an intuitive graphic technique generally recognized as the McCabe-Thiele diagram can be utilized to determine the operation efficiency or the variety of equilibrium stages for a specified separation. Our design, precision manufacturing, jacked at grade set up and propriety state-of-the-art coating know-how backs our reputation, making us the best solution for sand and mixture storage. Tank Connection's elevated water tanks function proprietary bolted RTP (rolled, tapered panel) design and the LIQ Fusion 7000 FBE™ coating system to ensure highest efficiency, low upkeep and superior aesthetics.

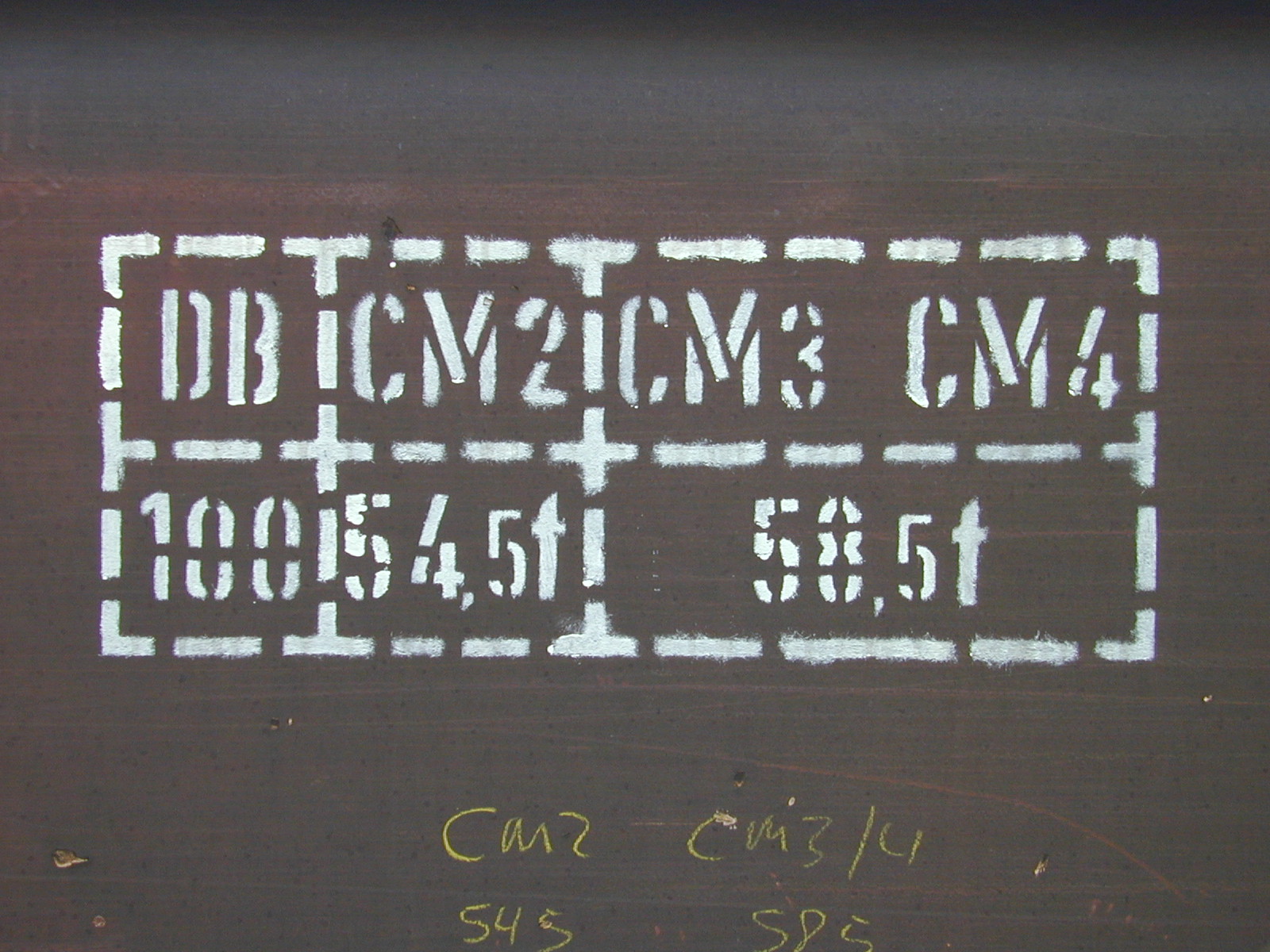

Where $ f_2 $ is the fraction of the column cross-section space or net area that is available for vapour move by way of the tray. The worth of $ f_2 $ is often zero.85~0.ninety five, that means that $ (1-f_2) $ is the fraction of the column area that is wanted for downcomers. The diameter calculation may be done utilizing vapour move fee within the rectifying section, stripping part, or the average, and one of these values will yield the maximum diameter. The largest calculated diameter could be passable for the design of most separation systems (Wankat, 1988). Figure 2.4 exhibits a schematic representation of liquid and vapour flows and compositions on any tray in the column denoted as Tray n. Because of the CMO assumption, each liquid and vapour circulate rates stay fixed throughout the tray.

The cost of building a small 300,000 gallon (1 million liters) water tower is round $300,000-$400,000 relying on local conditions and supplies used. Water tower top varies fairly a bit throughout the United States and even inside cities. You can also anticipate to pay round $400 and $1,800 per ton for metal. At about 2.2 pounds of steel per sq. foot of concrete basis or base, that value adds up quickly. That piping will embody digging over 400 ft of trench, laying the pipe, and then operating the pipe up the water tower.

The cost of building a small 300,000 gallon (1 million liters) water tower is round $300,000-$400,000 relying on local conditions and supplies used. Water tower top varies fairly a bit throughout the United States and even inside cities. You can also anticipate to pay round $400 and $1,800 per ton for metal. At about 2.2 pounds of steel per sq. foot of concrete basis or base, that value adds up quickly. That piping will embody digging over 400 ft of trench, laying the pipe, and then operating the pipe up the water tower.Please use and/or share my data with a Coldwell Banker agent to contact me about my real estate wants. Falling launch prices have given African nations a chance to send their own satellites into orbit. The US space company, Nasa, may even be delighted the flight has gone to plan. It has paid the company $2.8bn (£2.14bn) to develop Starship right into a lander able to returning astronauts to the Moon's floor by 2026. Elon Musk and SpaceX have grand designs that the rocket system will in the future take people to the Moon, after which on to Mars, making our species "multi-planetary". Catching the booster quite than getting it to land on the launch pad reduces the necessity for advanced hardware on the bottom and can enable fast redeployment of the automobile in the future. When it approached the landing tower, which stands 146m-high (480ft), its raptor engines labored to control its touchdown.

Estimate the Cost for 21779 Kelsey Square

The price of a small tank is between $1,000 and $5,000 while large tanks value upwards of $30,000. The price of construction of a water tower can differ depending on the dimensions and materials used. Water towers are used to retailer water for use in a constructing or space. They can be above or under ground, as well as buried or elevated tanks.