Increase capacity in your column with a tray design revamp

Attendant advantages embody much less energy utilization and decrease building costs. Mixing in water storage tanks has long been recognized as crucial to water quality. Headquartered in Louisville, KY, Caldwell Tanks, Inc. has been constructing innovative, personalized water and industrial storage tanks & vessels throughout North America since 1887. A distillation column, or tower, is used to separate liquid mixtures into particular person constituents based mostly on their boiling points. The liquid is heated to provide vapours which are then condensed, by cooling, back into liquid kind. The liquids are then collected in trays or plates positioned at totally different heights inside the column, their place based on the boiling level of every separate element. Industrial & Engineering Chemistry Process Design and Development, 20(2), Como funciona MND? 299.

Capabilities

As well, the above process is often used to troubleshoot operation issues in sensible distillation operations. For a distillation column design, if the general column effectivity, $ E_o $, is understood, then the actual variety of trays required or column peak for a specified separation may also be determined. TimberTanks are water storage tanks that mix the ageless fantastic thing about wood with the sturdiness of galvanized steel roofs and the trendy technology of versatile membrane liners for water containment. Wood staves are custom milled to form a barrel form and are banded together with galvanized metal bands to retain the round shape. The galvanized metal roof incorporates manufacturing unit shaped and punched excessive rib roof panels which create a durable and weatherproof roof structure.

TINYTIMBER TANKS

TimberTanks are solely constructed with wooden staves produced from sustainable or reclaimed lumber and with roofs containing a large share of recycled steel. These tanks are in-built our warehouse and shipped direct to the project web site. TinyTimber Tanks do not require a concrete foundation and every comes commonplace with a 25-degree standing seam roof with mosquito-resistant display screen, an overflow flange, hose spigot, and NSF-61 licensed liner. A tray column that's facing throughput issues may be de-bottlenecked by replacing a piece of trays with packings. The association, number and size of the holes are design parameters.

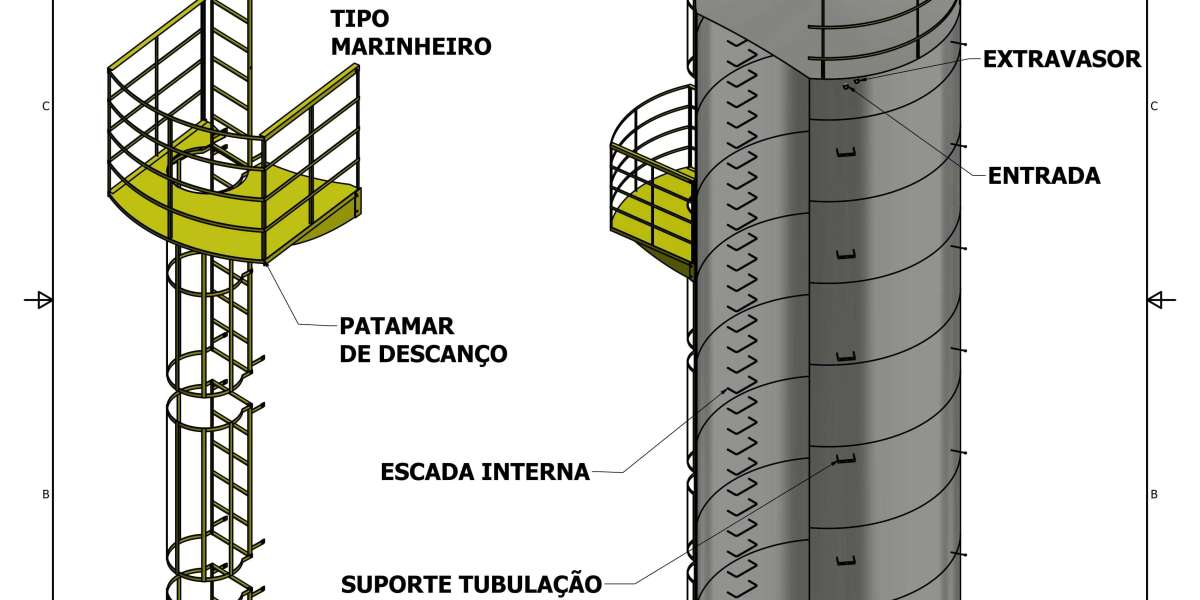

Where $ f_2 $ is the fraction of the column cross-section space or web space that is out there for vapour flow by way of the tray. The value of $ f_2 $ is usually zero.85~0.95, which means that $ (1-f_2) $ is the fraction of the column space that is wanted for downcomers. The diameter calculation can be accomplished using vapour flow fee within the rectifying section, stripping part, or the common, and one of these values will yield the maximum diameter. The largest calculated diameter could be satisfactory for the design of most separation methods (Wankat, 1988). Figure 2.4 shows a schematic illustration of liquid and vapour flows and compositions on any tray within the column denoted as Tray n. Because of the CMO assumption, both liquid and vapour move rates remain constant throughout the tray.

Also, your tanks which may be worn out or broken as a result of usage, it could be repaired in our manufacturing services. The one-piece, seamless tanks are molded from 100 % Food and Drug Administration (FDA) approved material and will not rust or impart any taste. The corrugated body permits it to stand upright making it extra durable and straightforward to make use of.The tanks are elastic to offer higher impact energy. In addition to our collapsible tanks, you could also try some of our polyethylene bulk storage tanks.

Ton Plastic Vertical Water Tank Raw Material Features

Collapsible Grey Water Tanks supply a excessive stage of flexibility, while nonetheless remaining rugged and sturdy in your liquid storage. All gray water tanks are made with high UV resistance and excessive abrasion properties. This gives them the power to be stored on a quantity of surfaces, while nonetheless remaining fully in tact. For elevated safety, a quantity of clients select to put berms or ground cloths beneath their tanks for added abrasion protection. Our horizontally buried tanks are available in capacities from four,000 litres to 9,000 litres.

Since 1986, Aquamate has designed, manufactured and put in hundreds of Poly Lined Steel Water Tanks in sizes from 5,000 to 200,000 Gallons. With greater than 30 years of analysis and development, an Aquamate metallic water tank is the primary choice for Durable, Reliable and Affordable giant quantity water storage. Aquamate provides an industry main 20 Year "No Service Costs" Warranty. Our steel water tanks have three primary applications – rainwater storage, fireplace suppression water storage, and well water storage. Tank-Mart.Com is proud to be America's largest supplier and distributor of plastic storage tanks, together with low profile holding tanks, customized water storage tanks, and more.

Online Storage Tank Distributor and Wholesaler

If we look at the technical particulars of those tanks; We see that its weight is 180 kilograms, its height is 240 centimeters, and julio-cesar-Domingues.mdwrite.net its materials thickness is 10 millimeters. In the sleeve part, a brass sleeve is used to make sure its suitability for food. Usage temperature charges are between the coldest -5 degrees and the hottest +50 levels. In addition, the lid half can be produced using polyethylene uncooked materials when it comes to its suitability for food. The chemical language name of these shops is linear low-density polyethylene "LLDP". The tanks produced utilizing this raw material have many benefits supplied to the person. In this context, polyethylene has two important properties.

We even have a 2,one hundred litre spherical buried water storage tank. Our state-of-the-art manufacturing facilities by no means use recycled raw supplies from recycled scrap or colorants that damage the tank. These tanks, that are produced with high quality raw supplies, are longer lasting, reliable and more sturdy. In this fashion, all our products are of top of the range and all products are under the assure of our firm for two yr.