4000 Gallon 316L Stainless Steel Vertical Vacuum Rated Storage Tank constructed by DCI, Inc. Rated 30 PSI/Full Vacuum @ 300 degF. X 10' Straight Side Height (15' Overall Height). 3" Center Bottom Outlet. Volume is approximate. Sanitary development. Insulated. Used- Stainless Steel Single Wall 2,four hundred Gallon Storage Tank, measures 69" diameter X 168" high.

It was scorching and full bodied, and we beloved that the control panel stored observe of when the espresso completed brewing. These coffee makers often come with large-capacity tanks. Some models can hold as much as 50 fl oz of water, enough to brew about 30 cups of espresso. This capacity is right for giant families or offices, lowering the frequency of refills. Stainless metal fashions, as an example, are sturdy and preserve the coffee’s unique flavor.

Ninja Pods & Grounds Specialty Single-Serve Coffee Maker

In addition to dimension, consider location and entry to your storage tank. Placing the tank in a convenient location for each set up and future upkeep will save time and effort. Local building codes may influence where and how one can set up your tank, so verify these laws earlier than making a choice. For houses with wells that wrestle to maintain up with water demand, including one or more storage tanks could be less expensive than drilling a deeper nicely. Half whiskey barrels only really come in one size and glazed ceramics are fairly, however the very giant ones come at a high value and may get very heavy.

They are watertight because of a state-of-the-art unhazardous sealant between the panels. Mixing in water storage tanks has long been recognized as important to water high quality. CB&I pioneered the transition from riveted tanks to welded steel tanks within the 1930s and developed the unique Watersphere®, Waterspheroid® and Hydropillar® storage tanks. Today, our water storage products can be found anyplace on the earth and may be constructed on both a union or non-union labor foundation.

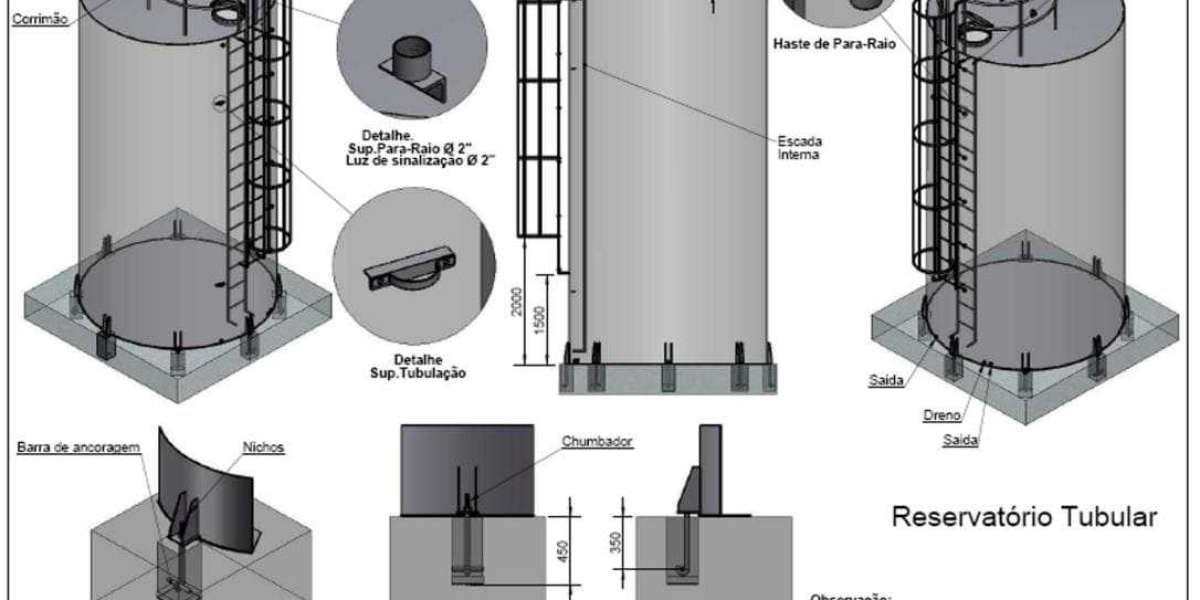

Tank selection is narrowed to bolted storage tank and field-welded storage tank building. Based on expedited schedule necessities and superior performance of manufacturing facility applied powder coat techniques out there for potable water storage, bolted storage tank development is selected. International location — order to set up full within weeks. Specializing in multi-column elevated storage tanks, our tanks offer a broad range of customizable options, including completely different heights, diameters, and supplies, tailored to meet the particular needs of our purchasers. Constructed with high-quality steel and coated with corrosion-resistant materials, our tanks ensure long-lasting sturdiness. Leveraging innovative engineering techniques, we ship cost-effective storage options which would possibly be simple to install and maintain.

Chemical Storage

In general, excessive stage effectivity requires excessive liquid circulate price on the tray to maintain a deep pool of liquid for long contact time. High vapour velocity is also necessary to generate adequate effervescent and excessive interfacial area for vapour-liquid contact, and so high stage effectivity as shown in the efficiency diagram in Figure 2.6. In contrast, low vapour and liquid circulate charges generally lead to low effectivity as a outcome of brief contact time and weeping in circumstances corresponding to sieve tray. However, at high vapour velocity, small droplets of liquid could be carried up by vapour to the highest tray, inflicting enough entrainment or even flooding, and much lowered stage effectivity. As well, excessive vapour move fee and deep liquid stage on the tray both lead to excessive stress drop for the vapour to circulate through the tray. Relative to "materials of building" selection, bolted storage tanks, shop-welded storage tanks, and field-weld storage silos are available in coated carbon metal, stainless-steel and aluminum development. All storage tanks and storage silos are customized for the applying and are available for installation at grade degree or elevated.

Applications of Cone and Dome Roof Tanks

One of the most typical and most recognizable designs, these tanks can hold roughly 2 million gallons of water. Many such tanks are designed with elaborate exterior colours and graphics representative of the services and communities the tanks serve. As the photos right here show, the shapes of the tanks can be simply as diversified as their floor look. Industrial & Engineering Chemistry Process Design and Development, 20(2), 299.